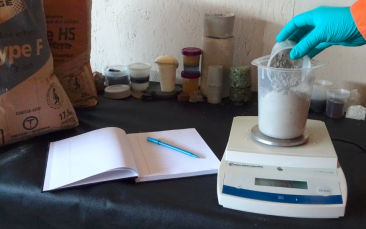

Lab Testing

Lab testing can be a critical component required to optimize grouting, backfill or chemical seal ring plans for a client’s individual projects and needs. We have extensive experience performing standardized lab tests, as well as conceiving new and innovative test methods to instill confidence in the design, materials, formulas, and to provide better expected site performance.

The summarized options below give an idea of our capabilities and experience:

- Formula design and optimization

- Additive/material testing

- Rheology/viscosity

- Reaction/set times

- Density

- Shrinkage

- Swelling

- Pressure filtration

- Low pressure – 100 psi

- High pressure – 1000 psi

- Unconfined compressive strength

- Bleed/separation/settling

- Injectibility

- Flowability

- Dissolution

- Washout potential under flowing water conditions

- Line plugging potential

- Temperature effects

- Particle size (sieve)

- Compatibility with various environmental conditions, chemistry differences, pH changes, preparation methods, etc.

- Performance or property changes under pressure, in wet/dry cycles, etc.

If any other lab testing is desired to be performed, please contact us and we will gladly discuss it and determine if this is a service that can be provided.

Any desired pilot-scale testing services are also available for consideration and can be performed either on the client’s site, or in-house.